About Hazeleger Kaas

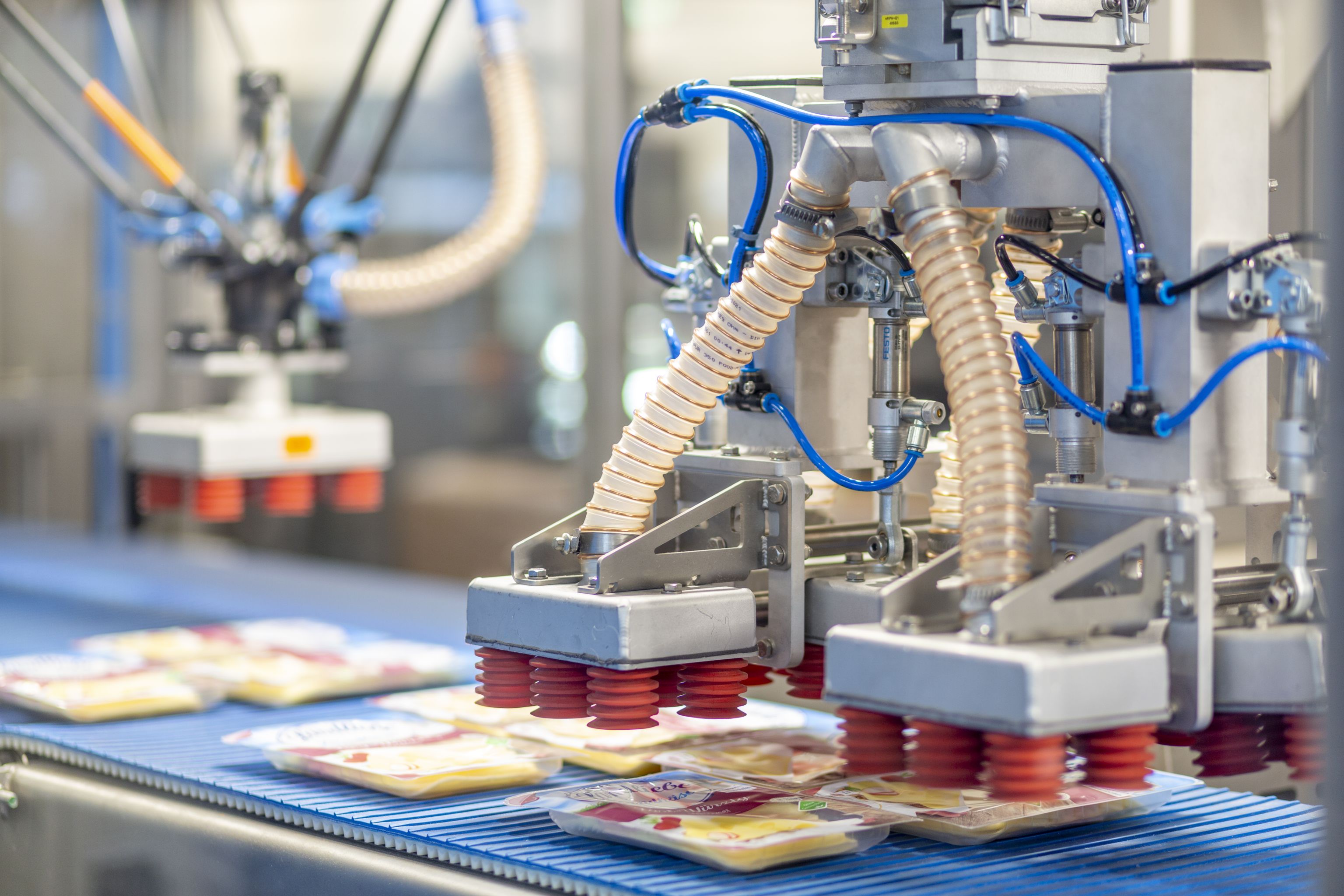

Over 100 years, Hazeleger has developed to become the cheese cutting and packaging specialist.

The strength of an

informal family company

Hazeleger is a true family company with an informal atmosphere and a horizontal organisational structure that ensures that we look out for our people and customers. We always make time for each other. We are an old company with a young team: a golden combination.

Leader

in packaging

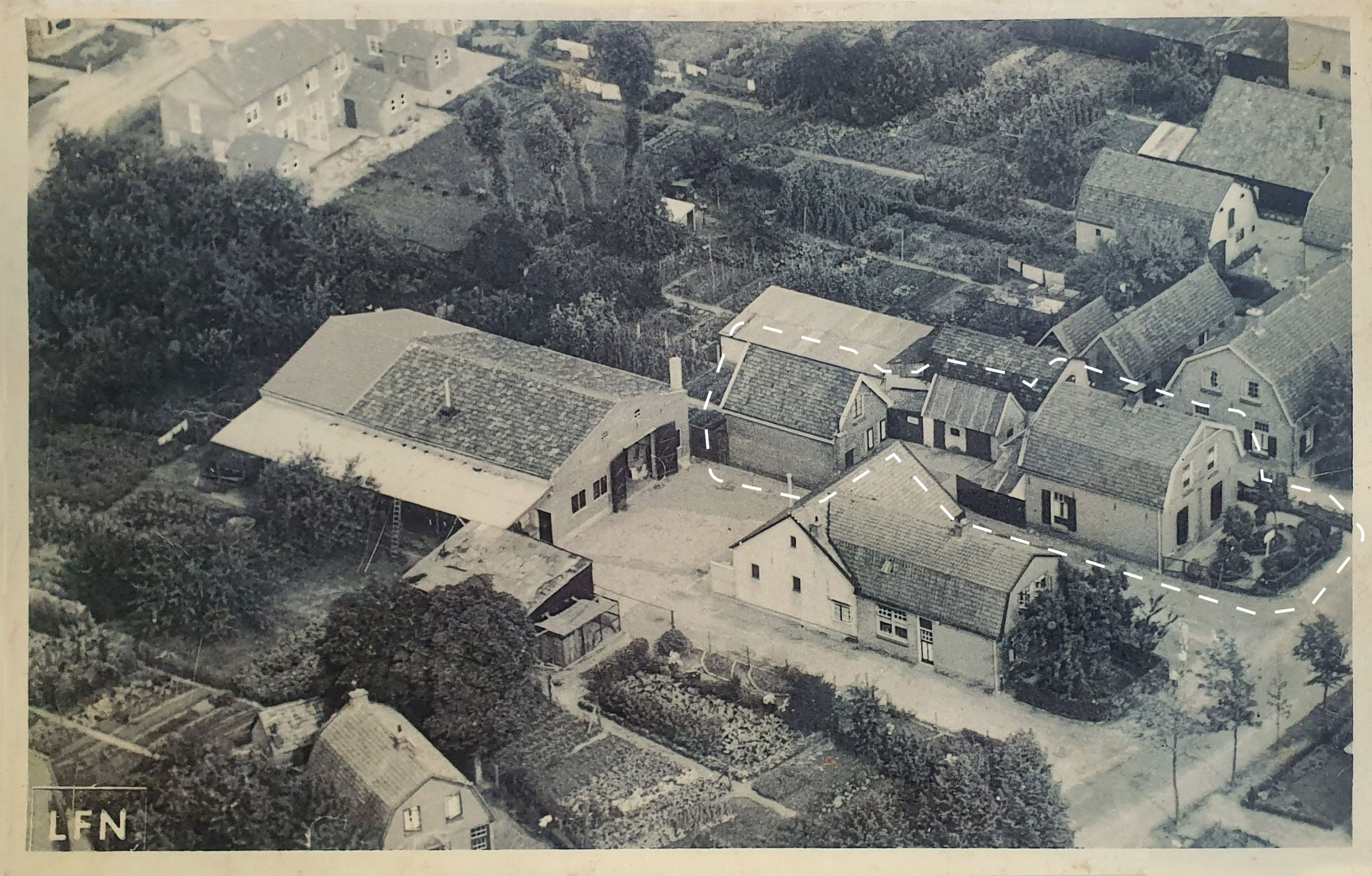

1922 Nijkerkerweg

1922

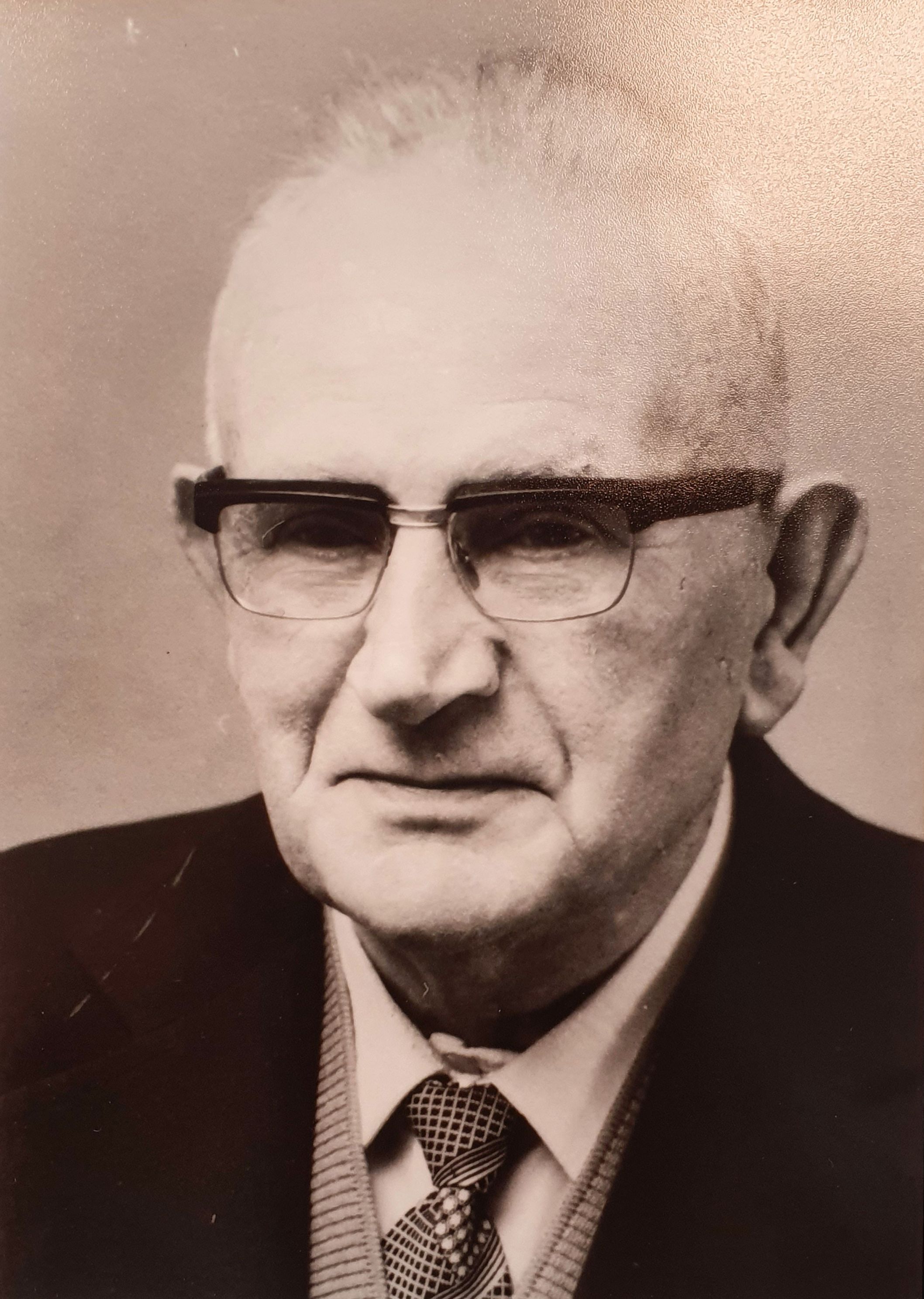

Foundation by Jannes

According to the registration in the Chamber of Commerce trade register, this took place on 22 June 1922. Jannes started hawking cheese on his transport bicycle.

1926

Horse and cart

From a newspaper article we can see that Jannes exchanged his transport bicycle for a horse and cart.

1934

Cheese and salt business

Jannes’ cheese business was listed in the international telephone book in 1934: hazeleger gzn., J., Kaas- en zouthandel. As many of his customers were farmers, Jannes added salt blocks for livestock to his range.

Directeur: Jannes Hazeleger 1922-1970

1943

Chamber of commerce registration

Jannes registered his company at the chamber of commerce on 3 april 1943. He also added ‘wholesaler’ as a business activity in addition to cheese business. The ‘salt business’ developed further as Jannes became ‘trader in agricultural salt’

1945

World war II

In the final years of the war, dutch farmers only produced sparse amounts of milk. Cheese production fell in the final year of the war to 500,000 kg, whereas it had been almost 2.5 Million kg in the mid-1930s. Cheese production returned to pre-war levels by 1948.

1950

The 1950s

In the years after the war, Jannes worked with his sons to expand Hazeleger kaas on Nijkerkerweg.

1962

Son Henk Hazeleger joins

By now Jannes was 58. His son Henk joined the company. Henk stayed living on nijkerkerweg, where the business address was also located. Later, Nijkerkerweg became known as Schoutenstraat. The private sale of cheese took place from the warehouse behind the house. Business customers received their deliveries by van.

1963

Private sale ends

The itinerant trade in dairy products to individuals ended altogether.

1970

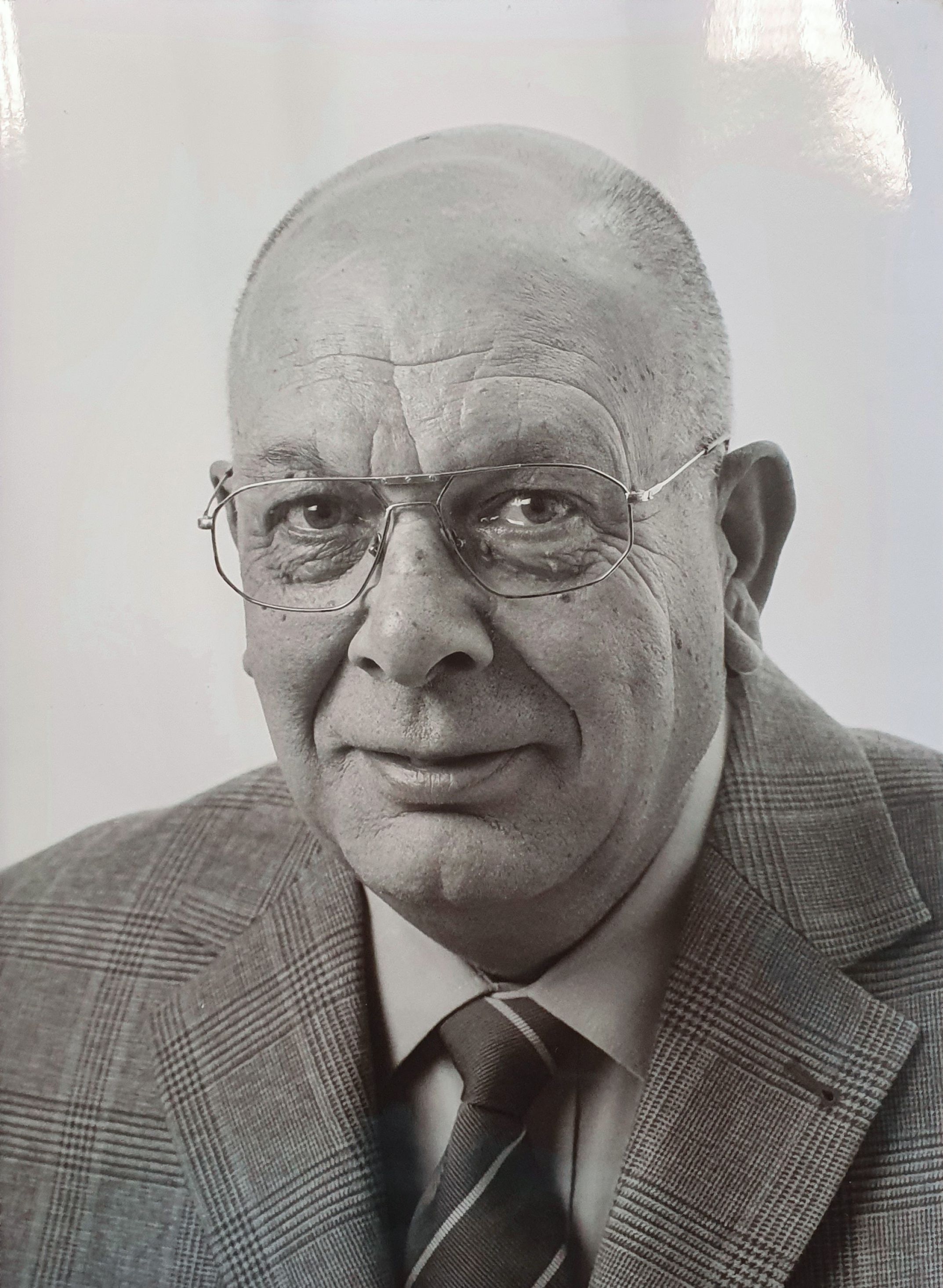

Henk hazeleger takes over the reins

By now Jannes was 66 and decided it was time to hand over the reins to Henk. Henk did not change much at the start but did focus increasingly on the sale of (whole) cheeses to grocers and milkmen. He also modernised the company in phases.

1972

Huge progress

An air-conditioning system in the warehouse ensured huge progress. This also kept the cheeses at the correct temperature in the summer so they could mature in the right way. Henk tentatively moved into cheese processing. Initially, he started packaging cheese in slices and packaged cheese pieces were also added to the range. Everything still took place manually in the utility room of the house next to the warehouse.

Directeur: Henk Hazeleger 1970-2002

1984

Reijer van Drie appointed

The business expanded and gradually Henk sought help to ease his long working days. Son-in-law, Reijer van Drie was an engineer and was prepared to help. He enjoyed the work so much that he stayed on.

Bellstraat

1988

Two new warehouses

At the end of the 1980s, Henk and Reijer decided to purchase a new plot of land on bellstraat where two new warehouses were built. Reijer was convinced that cutting and packaging cheese would be more profitable. According to him, that’s where the future of hazeleger kaas lay.

1990

Grating and cutting cheeses

The company started buying factory cheeses in bulk for grating and cutting at the new location. The grated cheeses were sold in 10 kg bags to local hospitality businesses and bakers. Slices of cheese were placed on meat trays and sealed. All still by hand.

1995

First steps toward automation

Reijer started searching for ways to automate parts of the process and introduced a cutting machine with conveyor belt and the first automated packaging machine.

Hanzeweg

1997

New production location on Hanzeweg

The focus on large-scale processing and packaging of cheese increased; an activity that demanded increasing space. Hazeleger opened the new production location on Hanzeweg in Barneveld. With his technical knowledge, reijer continued to further optimise and automate the process.

2001

First certificate obtained

Following the establishment of a quality system, the haccp certificate was obtained in 2001. This certificate and associated working method laid the foundation for the subsequent growth of Hazeleger Kaas.

2002

Reijer van drie appointed director

As things were going so well, 65-year-old Henk Hazeleger decide to leave the daily management of the company to his son-in-law for good.

Directeur: Reijer van Drie 2002-2016

2004

Growth

Hazeleger kaas had some ten employees. There were now four packaging lines on the shop floor. The established path of packaging and required certifications provided a fertile foundation for further expansion.

2009

Wim van rijn becomes co-owner

The company had now grown to approximately 50 employees. Wim van rijn became operational director and co-owner, before becoming full owner in 2016. Hazeleger kaas developed further in subsequent years to become a cheese packaging specialist.

Koningsbergenweg

2018

Production location on Koningsbergenweg

There were ambitious objectives for the new production location that became operational on Koningsbergenweg on the edge of Barneveld. The production location is an example of how industry and sustainability can go hand in hand.

Directeur: Wim van Rijn 2016-Heden

2022

Hazeleger kaas celebrates 100th anniversary

By 2022, Hazeleger Kaas was packaging 25 million kg of cheese per year; a task undertaken by some 300 employees. Their joint efforts have enabled the company to realise an annual turnover of €100 million.

We cut and

package cheese

Follow the cheese to the customer. Learn more about our cheese journey: from preparation to distribution.